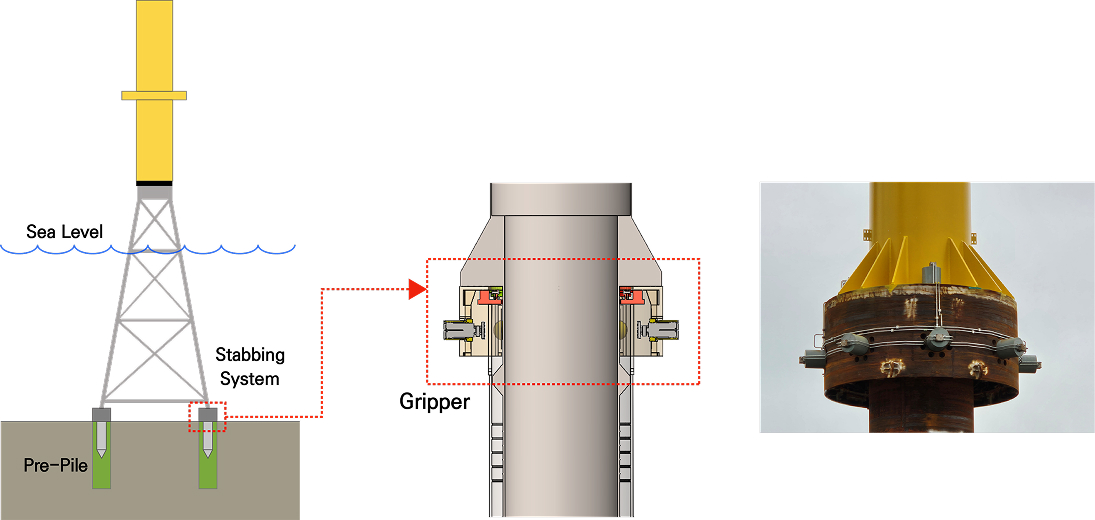

Gripper

- The Gripper is a device that temporarily secures the grouted connection between the jacket and pile, preventing quality degradation of grout caused by environmental loads before it achieves full strength.

- By applying Gripper technology, structural stability of the substructure can be ensured even under harsh environmental conditions.

-

Key Functions and Specification

-

- Gripper Capacity & Pile Diameter: The system can be customized to meet client requirements, offering optimal gripper specifications based on the pile diameter.

- Vertical & Horizontal Cylinders: These cylinders secure the jacket inclination and maintain horizontal alignment, effectively controlling relative movement during curing to enhance grout quality and structural stability.

- Gripper Control: A dual control system is provided via a dedicated topside control panel and an emergency subsea ROV panel.

- Standards Compliance: The system is designed to meet the EAC requirements specified in DNV-ST-0126.

Technology Development

K-BETS has successfully developed a gripper that matches global performance standards.

-

Development of a Hydraulic Gripper Prototype

Development of a Hydraulic Gripper Prototype

(Ministry of SMEs and Startups R&D) -

Development of Pile Gripper

Development of Pile Gripper

(Ministry of Trade, Industry and Energy R&D) -

Technology Development Agreement Signed with Trelleborg (Singapore)

Technology Development Agreement Signed with Trelleborg (Singapore)

Technology Development & Demonstration

Offshore Full-scale Trial of Gripper Technology (2024)

Project Location: Northern offshore area of Odo, Nokdo-ri, Ocheon-myeon, Boryeong-si, Chungcheongnam-do, Korea

Project Schedule: October 2024

Applied Structure: Boryeong Offshore Met Mast for Wind Resource Assessment

-

Fabrication & Assembly

Fabrication & Assembly -

Transportation to Site

Transportation to Site -

Installation in Progress

Installation in Progress -

Installation Completed

Installation Completed