Grouting

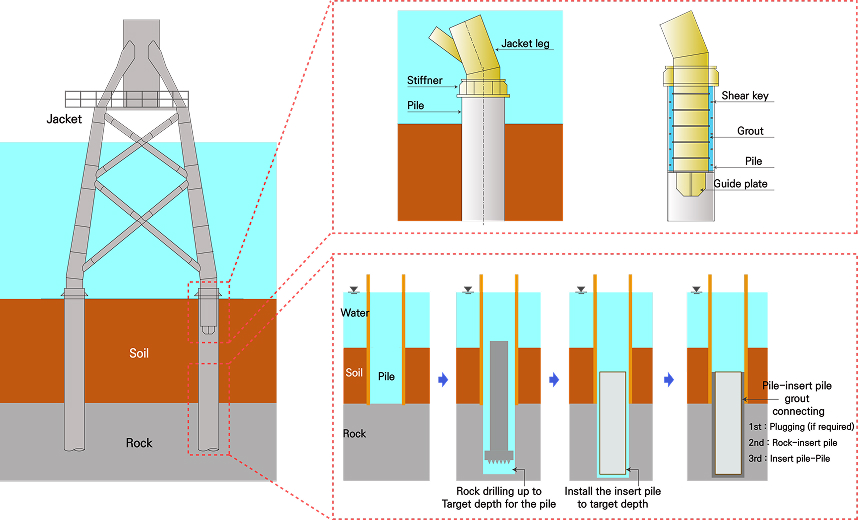

- Grouting, a critical process in the installation of offshore wind turbine foundation, is essential to ensuring the structural integrity and stability of connection interfaces. This procedure must be carried out with precision and in strict adherence to technical protocols that reflect the unique challenges of the marine environment.

- Offshore wind farm structure designs generally require high-strength grout materials certified by DNV.

- Backed by successful domestic applications of such certified materials, we provide reliable grouting solutions tailored to meet client specifications.

- K-BETS holds an official 'Boring and Grouting' license and possesses a grouting spread that complies with DNV standards. We offer a total service package that includes planning, logistics, and offshore execution.

- Our approach prioritizes safety, durability, and structural stability under various offshore conditions. Through tailored construction methods and proven engineering solutions, we aim to maximize customer satisfaction and ensure the long-term success of offshore grouting.

Our Capabilities include:

-

Consulting Suitable Grout Material and Application

-

Providing Offshore Grouting Execution Plan including Marine Fleet Operation

-

On-site Grouting Execution

-

Quality Control (QC), Quality Assurance (QA), and Risk Assessment (RA)

Work Procedure

-

- STEP 01

-

Installation of Mixer Plant - STEP 01

-

- STEP 02

-

Connection of Grout Inlet - STEP 02

-

- STEP 03

-

Connection of Grout Hoses - STEP 03

-

- STEP 04

-

Lifting and Transportation of Grout Material (Storage Yard → Mixer Plant) - STEP 04

-

- STEP 05

-

Feeding Grout into Dry Hopper - STEP 05

-

- STEP 06

-

Binder Pumping (Pumping Initiation) - STEP 06

-

- STEP 07

-

Disposal of Used Big Bags - STEP 07

-

- STEP 08

-

Grout Mixing and Pumping - STEP 08

-

- STEP 09

-

Sampling for Quality Testing - STEP 09

-

- STEP 10

-

Storage in Wet Hopper - STEP 10

-

- STEP 11

-

Quality Control Test follow DNV Standard - STEP 11

-

- STEP 12

-

Flowability Test - STEP 12

-

- STEP 13

-

Density Test - STEP 13

-

- STEP 14

-

Preparation of Cube Specimens - STEP 14

-

- STEP 15

-

Grout Injection - STEP 15

-

- STEP 16

-

Monitoring for Overflow and Emergency Stop Procedures - STEP 16