WaterJet Cutter

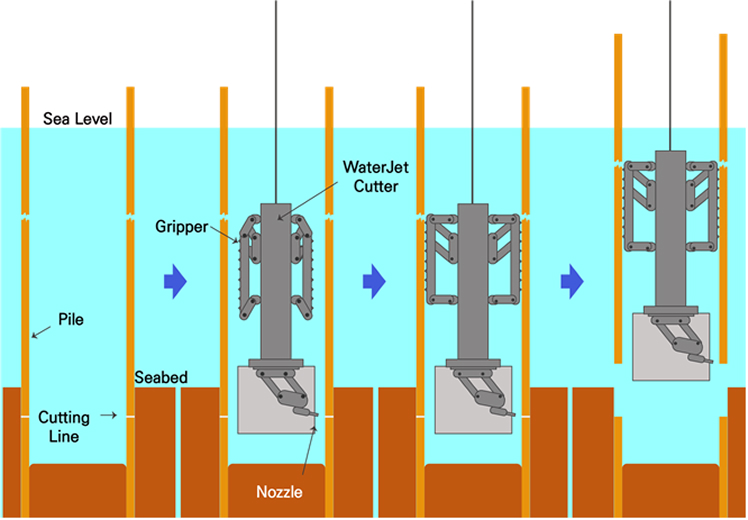

- A technology for cutting offshore piles internally using a water jet (abrasive + water pressure) cutting device. This non-contact method involves fixing the water jet cutter at the designated cutting position inside the pile. The spraying device rotates 360 degrees to cut the pile precisely and efficiently.

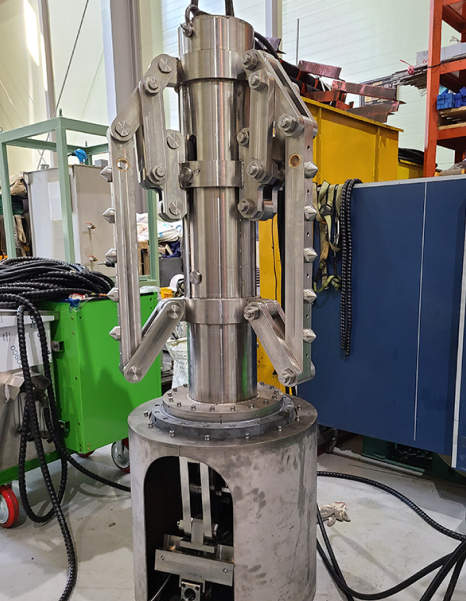

- Our waterjet cutting equipment was developed through the 'Offshore Plant Smart Decommissioning Technology Development Project.'. The abrasive jet is designed to operate at pressures of up to 2,400 bar, making it capable of cutting offshore pipes of various sizes, from small to large-diameter steel pipes.

-

Ensuring Workability and Safety

-

- Enables decommissioning and removal without underwater diver operations (eliminates risks associated with underwater work)

- No depth limitations (overcomes restrictions on manual operations below depths of 30m)

- Simplified work procedures and reduced operation time (cost savings through shortened project duration)

-

Key Aspects of Technology

-

- Pike-shaped fixing jig for enhanced holding strength

- 360-degree rotatable drive jig operation mechanism

- Optimized abrasive mixing facility and abrasive application

Products

-

Internal Cutter (WAJ-IP, Small)

Internal Cutter (WAJ-IP, Small)

(D: 550–800mm) -

Internal Cutter (WAJ-IP, Medium)

Internal Cutter (WAJ-IP, Medium)

(D: 750–1,200mm) -

External Cutter (Large) (WAJ-OP)

External Cutter (Large) (WAJ-OP)

(D: 2,800–3,200mm)

Technical Demonstration Cases

Performance Verification Test (Onshore) (2021)

Performance Verification Test (Offshore) (2023)